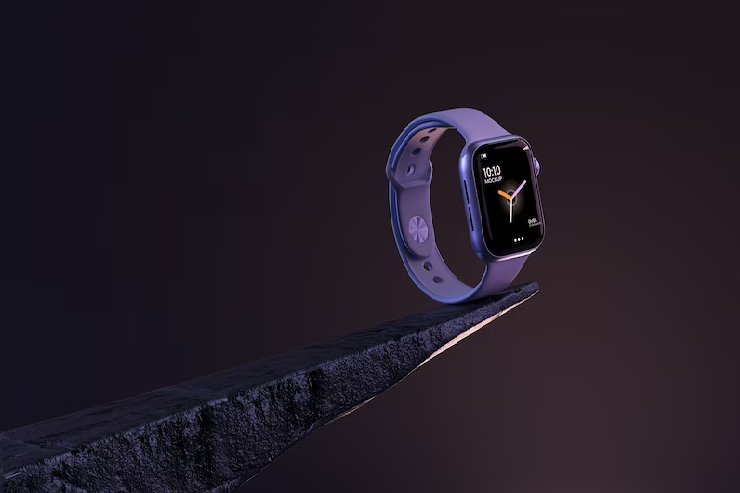

Apple Inc. has consistently been at the forefront of innovation in the ever-evolving world of technology. From pioneering the personal computer industry to redefining the smartphone with the iPhone, Apple has always pushed boundaries and set new standards. In recent news, Apple has been exploring 3D printing technology for producing its upcoming smartwatches. This move holds immense promise for the tech giant and the wearables industry. This article will delve into the fascinating world of 3D Printing and its potential impact on the production of Apple’s smartwatches.

The Promise of 3D Printing

3D Printing, also known as additive manufacturing, has gained widespread attention and acclaim for its ability to revolutionize traditional manufacturing processes. Instead of subtracting material from a solid block (as in traditional machining), 3D Printing adds material layer by layer to create three-dimensional objects. This process reduces waste and offers unparalleled design flexibility and customization options.

Apple’s Previous Ventures Into 3D Printing

Apple’s interest in 3D printing technology is not entirely new. The company has previously incorporated 3D Printing into its product development and prototyping processes. Apple has used 3D Printing to create prototypes of various components, allowing its engineers to iterate quickly and refine designs. However, the prospect of using 3D Printing in the mass production of smartwatches takes this interest to a new level.

Apple’s Venture Into 3D Printing For Its smartwatches.

-

Advanced Materials Selection

One of the critical considerations for Apple when adopting 3D printing technology is the choice of materials. The materials used in 3D Printing can significantly impact the final product’s quality, durability, and performance. In the case of smartwatches, materials must be lightweight, durable, and comfortable to wear for extended periods.

Apple has always been meticulous about the materials used in its products, and this will undoubtedly extend to its 3D-printed smartwatches. The company will likely explore a range of advanced materials, including specialized polymers, metals, and composites, to ensure that the smartwatches meet its high standards. These materials must also be biocompatible, as smartwatches often contact the wearer’s skin.

-

Innovative Design Possibilities

One of the most exciting aspects of 3D Printing is the creative freedom it provides in design. Apple’s design team can experiment with intricate and unique designs that would be challenging or impossible to achieve through traditional manufacturing methods. This opens up the possibility of creating smartwatches that perform exceptionally and stand out as fashion statements.

Apple has always emphasized the aesthetics of its products, and 3D Printing allows them to push the boundaries of what’s possible. The design possibilities are virtually limitless, from customizable watch bands to personalized watch faces.

-

Sustainability And Environmental Impact

Apple has been actively reducing its environmental footprint and promoting sustainability. 3D Printing aligns well with these goals. As mentioned, 3D Printing generates minimal waste, using only the material needed to create the object. This starkly contrasts traditional manufacturing, which often results in significant waste during the machining and molding processes.

By adopting 3D Printing for smartwatch production, Apple can demonstrate its commitment to sustainability and responsible manufacturing. This move could help the company reduce its carbon footprint and contribute to the broader effort to combat climate change.

-

Customization For The Masses

The era of mass customization is upon us, and consumers increasingly seek products that cater to their tastes and preferences. 3D printing technology allows Apple to offer customization previously impractical in mass production.

Imagine being able to select not only the color of your smartwatch but also the design of the watch face and the style of the watch band. 3D Printing can make this level of personalization feasible, enhancing the customer experience and driving brand loyalty.

-

Impacts on the Wearables Industry

Apple is known for setting trends in the tech industry, and its adoption of 3D Printing for smartwatches could have far-reaching effects. Other companies in the wearables industry may follow suit, looking to leverage the benefits of 3D Printing to stay competitive.

Additionally, this move could stimulate innovation in 3D printing technology itself. As more industries begin to explore the potential of 3D Printing for mass production, we expect to see advancements in materials, printing speed, and cost-effectiveness, making 3D Printing even more accessible for a wide range of applications.

-

Consumer Expectations And Market Impact

Apple’s reputation for quality and innovation means consumers have high expectations for its products. If Apple successfully implements 3D Printing for smartwatches and delivers on its promises of superior design, customization, and sustainability, it could further solidify its position as a leader in the wearables market.

The market impact could extend beyond just smartwatches. It may influence how consumers perceive and value 3D printed products, potentially paving the way for broader adoption of 3D Printing in consumer goods.

Also Read: IPhone 15 Unveiling In 1 Month: 10 Insights On The Next Apple Release

The Benefits of 3D Printing For Smartwatches

-

Design Freedom

One of the most significant advantages of 3D Printing is its design freedom. Traditional manufacturing methods often come with limitations in terms of geometry and complexity. With 3D Printing, Apple can design intricate and customized components for its smartwatches, allowing for improved aesthetics and functionality.

-

Reduced Material Waste

Traditional manufacturing processes generate significant material waste, which can be both costly and environmentally damaging. 3D Printing, on the other hand, is an additive process that produces little to no waste. This aligns with Apple’s commitment to sustainability and reducing its environmental footprint.

-

Speed And Efficiency

3D Printing can streamline the production process by eliminating the need for tooling and molds, which can be time-consuming and expensive to create. This means that Apple can bring its smartwatches to market faster and respond more quickly to changing consumer demands.

-

Customization

In the era of personalization, consumers are increasingly seeking products that reflect their tastes and preferences. 3D Printing allows for easy customization, enabling Apple to offer customers the option to personalize their smartwatches, from color choices to design details.

-

Cost-Effective Prototyping

3D Printing is an invaluable tool for prototyping. Apple can rapidly create and test various design iterations, saving time and resources during product development.

Challenges And Considerations

While the potential benefits of using 3D Printing for smartwatch production are clear, there are also challenges and considerations that Apple must address:

-

Materials

Ensuring that the materials used in 3D Printing are durable, lightweight, and suitable for wearables is crucial. Apple must carefully select materials that meet these criteria while maintaining product quality.

-

Scale

Mass production using 3D Printing can be a logistical challenge. Apple must invest in advanced 3D printing technology and processes to meet the high demand for its smartwatches.

-

Quality Control

Maintaining consistent quality in 3D printed components is essential. Apple must develop rigorous quality control processes to ensure every smartwatch meets high standards.

-

Regulatory Compliance

The wearable technology industry is subject to various regulations and standards. Apple must ensure that its 3D-printed smartwatches comply with all relevant regulations, particularly regarding safety and health.

-

Cost Efficiency

While 3D Printing offers numerous advantages, it can be expensive compared to traditional manufacturing methods. Apple must find ways to make 3D Printing cost-effective for mass production without compromising quality.

Conclusion

Apple’s exploration of 3D Printing to produce its upcoming smartwatches represents a bold step into the future of manufacturing. The potential benefits, from design freedom to sustainability, are significant. However, Apple must address the challenges and considerations associated with this technology to ensure a successful transition to 3D Printing on a large scale.

As consumers continue seeking functional, personalized, and sustainable products, Apple’s move towards 3D Printing aligns with these evolving trends. While we await further updates on Apple’s 3D printing endeavors, it is clear that the tech giant is committed to pushing the boundaries of innovation again, shaping the future of wearable technology.